How clean is the offshore wind industry, really? Industry insiders are well aware that while it is one of the cleanest forms of electricity generation, there is still a carbon cost embedded in the manufacturing, installation, operation and maintenance of offshore wind farms, including mining for the raw elements, and producing concrete, steel, and other materials. This adds up to a carbon footprint which - while small when compared to coal power generation - is still significant, especially at scale.

Some forward-thinking businesses - both in the offshore wind industry and other verticals - are already trying to aggressively reduce emissions through green steel production, recycling old turbines, and reducing the impact in other parts of the supply chain. But what they may not realize is that a sizable opportunity also exists to make the marine service segment supporting the offshore wind industry with vessels during installation and maintenance much cleaner today. Their activities are major contributors to greenhouse gas emissions from wind power, at around ~10 g CO2-eq./kWh, or over one quarter of total emissions generated by offshore wind.

An opportunity to reduce emissions, save money, and accelerate the growth of the industry

When you consider the complexities of the offshore wind energy supply chain, the number of companies involved, required resources, and the sensitivity to disruption by changing weather conditions and harshness of the marine environment, it becomes clear that there are many factors that can influence efficiency. And these lost opportunities for efficiency can have a big impact. Studies from IRENA show that although the last decade has been a remarkable period of cost reduction, electricity generated by offshore wind turbines is still more than twice as expensive as that generated onshore.

So if you could optimize the supply chain and use your offshore assets more wisely, you would drive down the cost of building and maintaining offshore wind infrastructure, and at the same time, reduce the carbon footprint from your marine services.

Many paths to reducing emissions

In theory, there are many ways to improve efficiency and reduce emissions. By synchronizing all your activities and ensuring all vessels arrive at their destinations just in time, deep and significant emissions cuts can be achieved. In fact, based on our own data, 33% in emissions reductions and 20% in operational costs savings are possible right now.

But how to achieve this?

When planning, it means taking multiple variables into account, including weather conditions, tide, and the availability of spare parts and technicians. Cargo space should always be optimized so no trips are wasted. Vessels and even organizations can pool demand and coordinate their assets to work more efficiently. And importantly, the biggest cuts can only be realized when supply chain partners work together, and have the right data available to analyze, optimize and automate many of these processes.

Digitalization is becoming a key enabler for operational efficiency

These opportunities for operational efficiency have long been known as potential areas for optimization. But until relatively recently, the potential for making the optimizations a reality have been out of reach, due to factors including disconnected vessels, equipment, and crew.

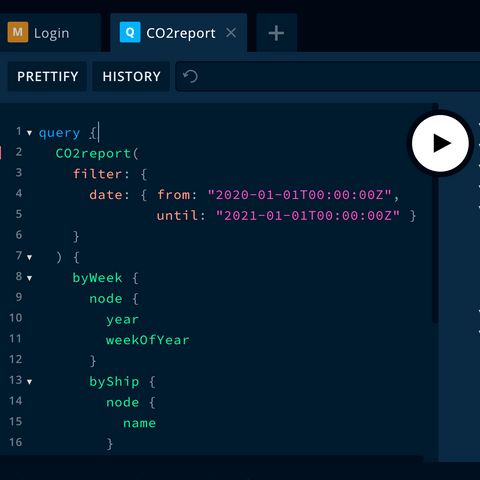

But this is changing quickly. New technologies such as the Industrial Internet of Things, APIs, and cloud computing mean that it is now possible to connect equipment, sensors, and people on board, and share data in real time, providing complete visibility into the operation of the vessel and adjacent supply chain activities. The types of data available to optimize operations include an abundance of real-time statistical information on every vessel activity, including data from digital logbooks, navigation equipment, fuel consumption and emissions, port handling, offshore turnaround times, and more. And the technologies also enable better communication with the crew, marine service providers, and their supply chain partners, meaning they can make fast, objective decisions to optimize operations.

It's time for offshore wind operators to get involved

Right now, some innovative vessel owners are already improving operational efficiency with these kinds of technologies. And there are many more vessel owners who see the potential.

However, something is stopping widespread action to sharply reduce emissions through operational efficiency. A common dilemma within the maritime industry is that when owners invest in the technology, operators benefit. And since there is no financial incentive for owners to invest, deadlock to action is the result.

The good news is that as an offshore wind operator, there are a number of things you can do to trigger this easy opportunity to reduce emissions and make one of the cleanest sources of electricity even cleaner.

The first and easiest thing to do is simply talk to and partner with marine service providers who share your values and goals around carbon emissions reductions. As mentioned above, the biggest cuts can only be realized when supply chain partners work together. And there are a number of service providers that already are, or want to, invest in solutions to improve their operational efficiency and drive down their emissions. So the power of proactive communication may in some cases provide the spark that leads to collaborative action in this issue.

We have already established that the biggest opportunity is that these new technologies have proven huge potential cost savings. So second, you can formalize your goals by adding emissions targets to your tender, including conditions on how to set benchmarks and targets, and how to measure and communicate the results transparently. This will give your prospective suppliers a financial incentive to break the deadlock to action and make the investments that are lacking today.

And third, one way to guarantee that your marine service providers have the technology they need to measure, communicate, and reduce carbon emissions is to invest in yourself, perhaps as a part of your own internal Scope 3 emissions reductions goals. These new technologies provide full visibility and control over your emissions for optimization and reporting. And with subscription pricing models, there is no need for large upfront costs. Finally, results can be realized in as quickly as a couple of months. This means there is a strong business case for your investment.

Together we can make the cleanest scalable source of electricity even cleaner

With a cumulative installed capacity of offshore wind at just 34 GW at the end of 2020, offshore wind has around one-twentieth of installed capacity as that of onshore wind. Improving operational efficiency offers a fast and sustainable way for marine service providers to reduce the carbon footprint of the offshore wind industry, and make it more cost-competitive with onshore wind. However, a key blocker to accelerating progress is the question of how marine service providers are incentivized to invest in and utilize these new technologies. Together, industry players including offshore wind operators have a huge opportunity to win efficiency gains, reduce their carbon footprint, and provide a major net benefit to society.

A version of this article was first published on NS Energy.