It is commonly accepted that there are hundreds of things that can be optimized on and off your vessels. And virtually everyone agrees that with focus, effort, and creativity you can unlock these efficiencies and gain an unbeatable competitive advantage.

Yet despite the potential, most maritime businesses leave efficiency gains, excessive carbon emissions, and money on the table by not acting to improve efficiency in the ways that they can.

What a record-breaking cycling team can teach maritime businesses about performance gains

The British cycling team was unimpressive for most of its history. From 1908 to 2008 British riders won just a single gold medal at the Olympic Games.

But in 2003, they took a different approach. Their new performance director believed that if you broke down every tiny aspect you could think of that goes into riding a bike, look at the data, and make multiple small improvements across every aspect of an athlete’s life, you would eventually gain an unbeatable competitive advantage. This “marginal gains” approach led to dramatic results. By the 2008 Olympics, the team that had one medal in a century went on to win 60 percent of the gold medals on offer.

The use of data in sports has exploded over the last decade, and there are parallels with the maritime industry in terms of the potential for looking at data to unlock gains. And you don’t need to be a data scientist, or even have special skills. Today, any capable fleet manager or maritime operations specialist can achieve drastic improvements in operational efficiency, as long as they have the appropriate tools.

Here are three very practical, simple steps you can take to build efficiency-driven competitive advantages, inspired by the GB cycling team but with real-life practical examples.

1. Start by measuring everything

When you think of optimizing a cyclist’s performance, you would probably think of things like bike design, training techniques, nutrition, and so on. However, there are numerous other things which may not be obvious, but can have an impact, such as testing different types of massage gels to see which one led to the fastest muscle recovery, or figuring out the best pillow for each rider to ensure a good night’s sleep.

When we talk to Fleet Managers today about what their vessels and crew are doing they have a very good understanding of the complexities of the operations their vessels and crew are involved in. But often what they don't know is what is actually happening offshore - and the reality can be surprising. For example, your logbooks may have “offshore handling” as an activity entry. But what is actually involved in offshore handling? It is actually a collection of things; DP setup, moving in, gangway transfer, crane handling, moving out, waiting due to weather or other unforeseen circumstances, and so on.

If you cannot objectively see how your time and resources are spent, important opportunities for optimizations can go missing. Using modern tools such as Onboard’s Digital Logbook enables you to measure the operation of your fleet, in a granular detail, as it is, free of assumptions and biases. Activities that are wasteful and which require unusually high amounts of resources quickly become visible. And only when you start measuring you can establish whether or not your actions to improve performance are actually working.

2. Unlock gains from unexpected places

Washing your hands properly may not be the first thing that comes to mind when training an elite cycling team. But as they looked at the data, the British team realized that the average cyclist loses some days of training over the course of several years to infections, which can in many cases be avoided by having clean hands. It was estimated that over the course of four years, this gave the cyclists an extra five days of training - perhaps enough to gain a few seconds on the track.

Often in our industry we focus on the performance of vessels, and start by making sure the vessel is handled correctly, engines are working properly, the hull is clean, and so on. Although these are indeed important optimizations that can result in substantial gains, once you start measuring everything, tasks that were previously obscured become obvious and new potential for improvement are revealed.

One maritime business working with Onboard had an analogous experience while trying to optimize their towing operation. After their initial focus on their vessels, the crew and the pilots they were working with, they realized the biggest improvement was not related to any of them. Rather, they realized that one of the main drags on efficiency was the performance of the linesmen. By focusing their optimization efforts on an activity that is officially outside their scope, they were able to reduce the average turnaround time by 30 minutes. This saved a significant amount in fuel and personnel costs, and significantly improved terminal efficiency.

3. Synchronize your supply chain

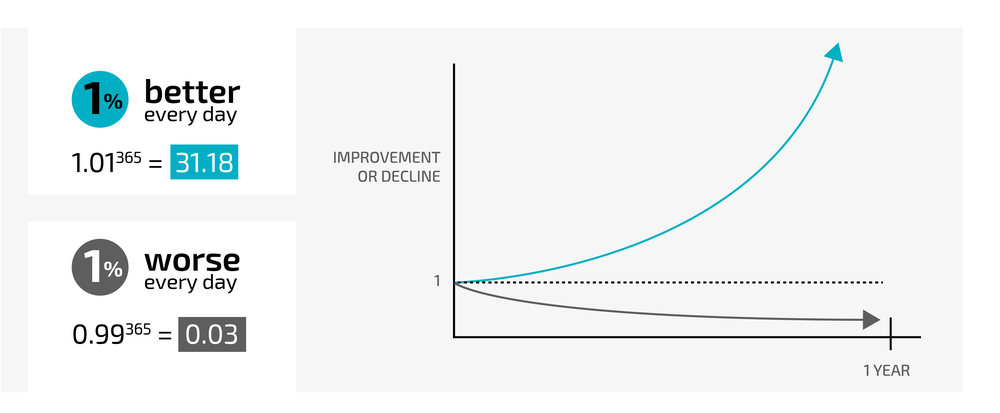

When you watch competitive cycling the focus is on the cyclists. But behind each winning cyclist is a supply chain of incremental competitive advantages, in the shape of trainers, doctors, nutritionists, equipment designers, masseurs, and more, working in harmony to deliver the optimal outcome. The impact these compounding small improvements can have on performance over time is astounding. For example, if you can hypothetically get one percent better each day for one year, you’ll end up thirty-seven times better by the time you’re done.

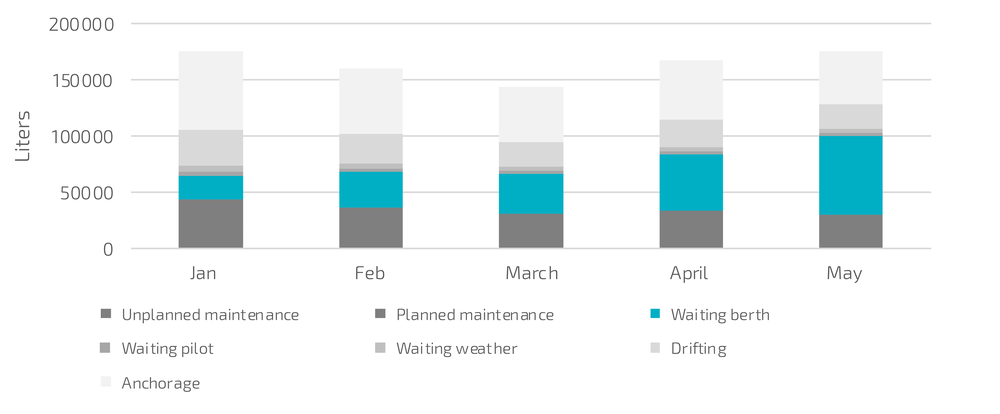

The same potential applies to maritime businesses today. Currently, a great deal of time is spent idle, waiting for cargo to be delivered, berth availability, nautical services, the right weather conditions, shifts to begin, equipment to be fixed, and so on. If you can synchronize these activities throughout yout maritime supply chain, reductions in vessel fuel consumption of up to 30% and operational cost savings of 20% are already completely realistic.

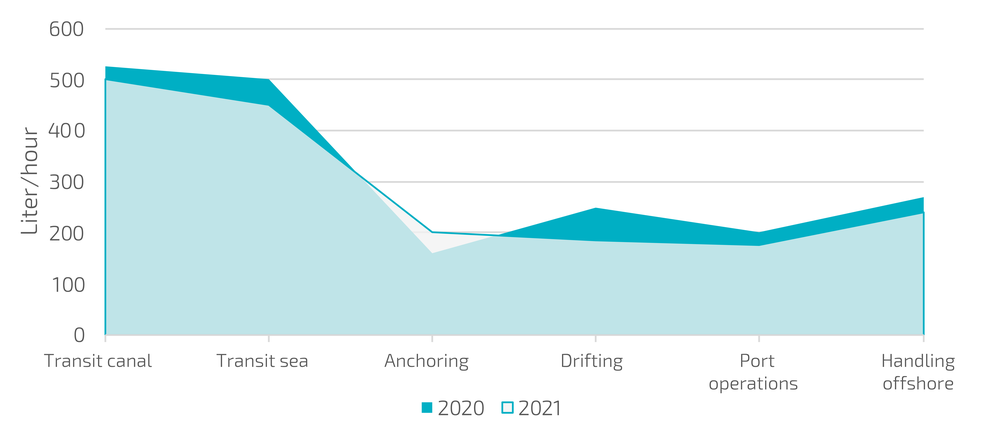

An example is Acta Marine, an offshore logistics support provider supplying energy infrastructure in the North Sea. Due to the geographical nature of the platforms they supply (strong tides, and shallow water), if a vessel departs too late, there is an enormous impact on fuel efficiency. To ensure that its vessels run with the greatest possible fuel efficiency under the tide, weather, and logistical circumstances they are in, they make sure the vessel is fully loaded half an hour before low tide, and then they give the captains freedom to choose exactly when to leave, based on the factors such as wind and water depths. The captains take advantage of the tides to go to the platform using a minimum of fuel, unload, load, and return, all based on hard data and the effective exchange of this data with tools such as the Vessel API that enable activities to be synchronized in port, offshore and on board. And yes, as their KPI for this initiative was fuel efficiency, the organization has seen a sustained reduction of 33% percent in fuel consumption.

How maritime business can get started

Maritime businesses are large organizations with many stakeholders and dealing with numerous uncertainties, on a more complex level than cycling. Combined with ever growing complexity of information technology and with buzzwords dominating much of the conversation, you could easily find your organization and yourself paralyzed.

By following the three simple steps outlined in this article and by using easy-to-implement solutions such as Onboard, you can quickly start your journey to become more data driven, and rapidly increase efficiency and your organization's level of digital maturity. And because we are at a stage where so many efficiency gains are just up for grabs you could quickly find yourself leading the genuine digital transformation of the industry.

To find out more, contact us.