Finally, a Platform That Plays Well with Others

System integration on board is complex and fragmented. Onboard simplifies it with one installable platform—offering high-fidelity data, advanced analytics, and full interoperability with any external system or application.

-

Connect Ship

Maximum compatibility

Connect any machine, system, or sensor—regardless of brand, or protocol. The Onboard Gateway captures high-frequency data locally and syncs it securely to shore, even in low-connectivity environments.

-

Digital Logbook

Context-Rich Insights

Combine sensor data with crew-entered registrations to create the full picture. Understand not just what happened—but why it happened, and how to act on it.

-

Dashboards

Powerful Analytics

Turn data into decisions. Use real-time, customizable dashboards to track KPIs, spot trends, and improve performance across your fleet.

-

Vessel API

Unified

AccessAccess all monitoring data via a single, standardized API. Easily integrate with any external analytics tool and keep your workflows flexible—no silos, no lock-in.

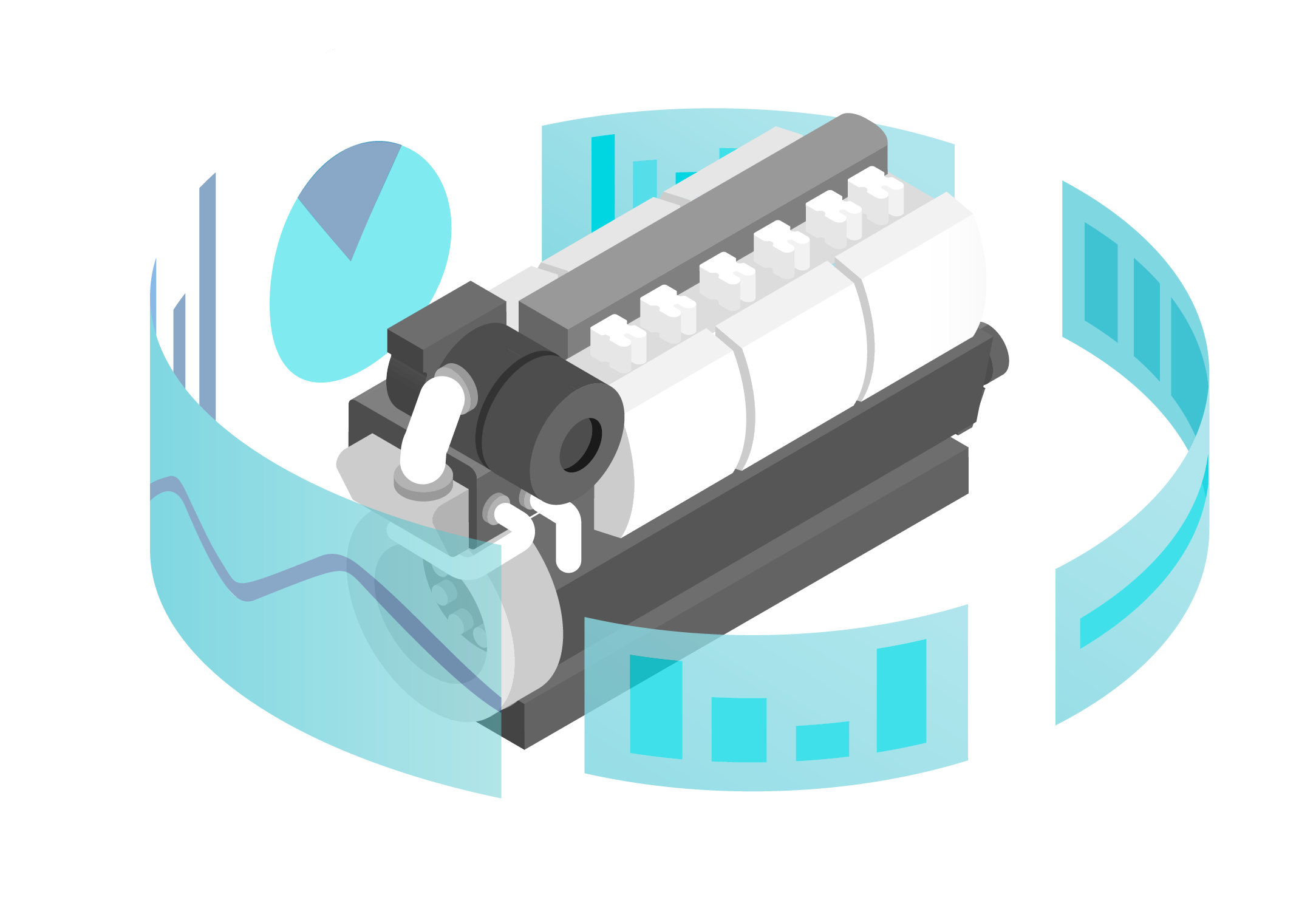

Condition monitoring without the hassle

Protect your rotating equipment on board such as engines, generators, gearboxes, thrusters, pumps, hydraulic power packs, and so on with industry-leading intelligent vibration sensors.

These sensors simultaneously monitor impact (acceleration peak), fatigue (average velocity), friction (average acceleration), severity (crest factor) and temperature (Degrees Celsius) to detect a variety of mechanical issues, such as unbalance, looseness, misalignment, bearing failure, gearbox mesh tooth fault or cavitation.

Set individual alarming thresholds for every machine, and optimize service intervals based on the actual condition of the equipment, before major damage.

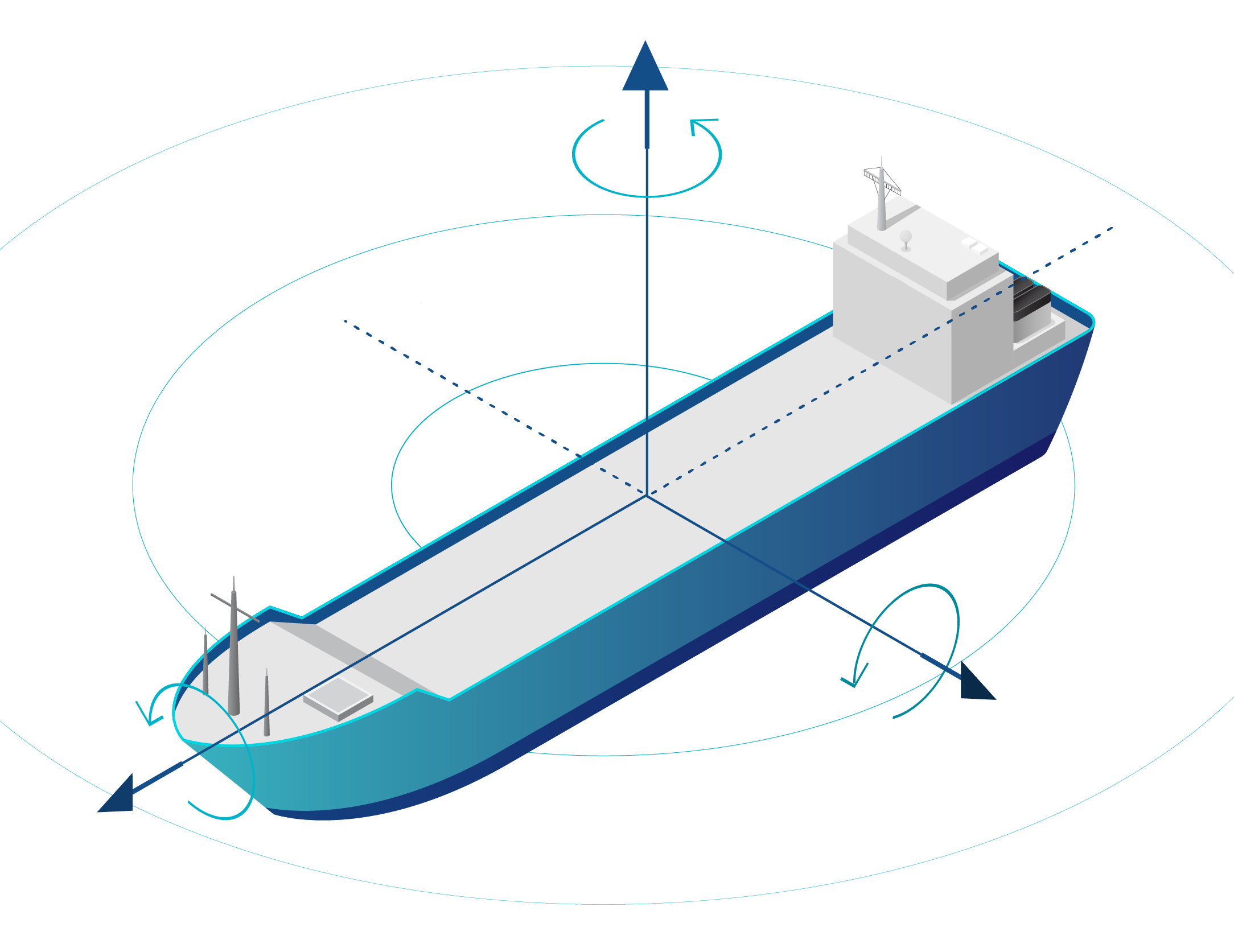

Motion monitoring that enables you to see and achieve more

Motion monitoring enables you to accurately measure the roll, pitch, yaw and heave motion of vessels. With Onboard, you can combine motion indicators with weather and navigational sensor readings and other vessel operational data.

Motion data is available for real-time decision support and stored for evaluation and reporting. Use cases include work ability analysis, trim optimization, and the ability to reduce the risk of cargo damage.

Motion reference unit

- Roll and pitch accuracy: 0.01°

- Angular range: ± 45°

Supported engine interfaces

- Modbus: TCP / UDP / Serial

- CANbus: J1939 / CAN FD

- NMEA: TCP / UDP / Serial

Vibration sensor

- Frequency range: 2…10000 Hz

- Acceleration peak (a-Peak): 0...50 g

- Average velocity (v-RMS): 0…0.045 m/s

- Average acceleration (a-RMS): 0…490.3 m/s²

- Surface temperature: -30…80 °C

- Crest factor: 1...50

Engine monitoring that works with every engine

Monitor critical performance parameters of your engines such as fuel rate, engine speed, load, oil pressure, coolant temperature, running hours, and so on. Onboard is brand agnostic, and works with every engine or engine control unit with a CANbus or Modbus interface.

Measurements provide useful information about engine performance and condition. This helps you troubleshoot engine conditions and potentially eliminate a service technician’s preliminary visit to a vessel.